The industrial landscape and XR technology could make for perfect partners. Manufacturing companies are constantly facing increasing pressure to deliver innovative new products and solutions at a rapid pace. Responding to rising demand forces these companies to constantly invest in better teams, processes, and technology.

Extended Reality has the capacity to transform virtually every part of the go-to-market strategy for the industrial space. From creating and exploring new product opportunities in virtual reality, to support teams via augmented and mixed reality, the opportunities are endless.

As the market for XR accelerates, growing at a rate of around 57.91% CAGR, industrial teams are on the precipice of a revolution.

The biggest challenge for many innovators ready to embrace the extended reality world, is building a business case capable of converting all company shareholders.

Here’s how you can get started with your business case.

Step 1: Find the Biggest Roadblocks for Your Company

For most manufacturing and industrial companies, XR represents an incredible opportunity to fix some existing problems with development, collaboration, and innovation. One of the easiest ways to get buy-in for a business case, is to find existing issues different forms of extended reality can solve.

For instance, if the pandemic made it increasingly difficult for your manufacturing company to bring team members together for ideation and product development, you can look into the benefits of virtual reality and digital twins. These tools allow more team members to work together in a shared “virtual” space when real-world interactions aren’t possible.

Alternatively, if you’re concerned about the costs of sending subject-matter experts to field locations, you can consider using augmented and mixed reality tools to connect people in the field with team members wherever they are. A pair of smart glasses could allow a subject matter expert to annotate a piece of machinery and deliver advice in real-time.

Step 2: Highlight Faster Innovation

Aside from fixing existing problems, XR also has the potential to significantly improve the speed with which manufacturing and industrial companies can innovate and create. As digital transformation in the modern world continues to accelerate, and consumers search for new solutions, manufacturers are under serious pressure to deliver solutions fast.

According to reports by PWC, bringing AR and VR into product development could generate a massive GDP boost of $360 billion by 2030, simply by accelerating go-to-market opportunities. Through innovative XR solutions, employees in the industrial landscape access a wider variety of tools to help them build the perfect products faster.

It’s even possible to experiment with materials and ideas which may not have been an option for companies in the past, due to high prototyping costs. At the same time, once a digital twin of a product or prototype is created, it’s easy enough to provide shareholders and stakeholders with a comprehensive tour of the solution from a distance.

Step 3: Consider Safety and Compliance

XR in the manufacturing and industrial sectors isn’t just an excellent tool for innovation and rapid growth. These tools could also be critical to keeping professionals safe in a somewhat unpredictable landscape. Leaders in the industrial space are required to provide their team members with a certain level of care, as well as the right tools to ensure their safety.

Extended Reality solutions can help to keep team members secure in a range of ways. The right innovative VR and MR solutions can train staff on how to use complicated and sometimes dangerous pieces of machinery, without the need for business downtime. The same tools can also provide users with real-time access to information and guidance when on the job.

In the post-pandemic era, the use of extended reality tools also allows manufacturing companies to provide partners and shareholders with tours of manufacturing equipment without exposing them to potentially dangerous scenarios. All the while, these solutions enhance the opportunity for collaboration at a distance, with minimal risk for contamination.

Step 4: Highlight Potential Process Improvements

Running a successful business in the industrial landscape means constantly searching for ways to manage a more efficient and productive team. XR can give employees access to more of the guidance, support, and information they need in any given moment, to boost business results.

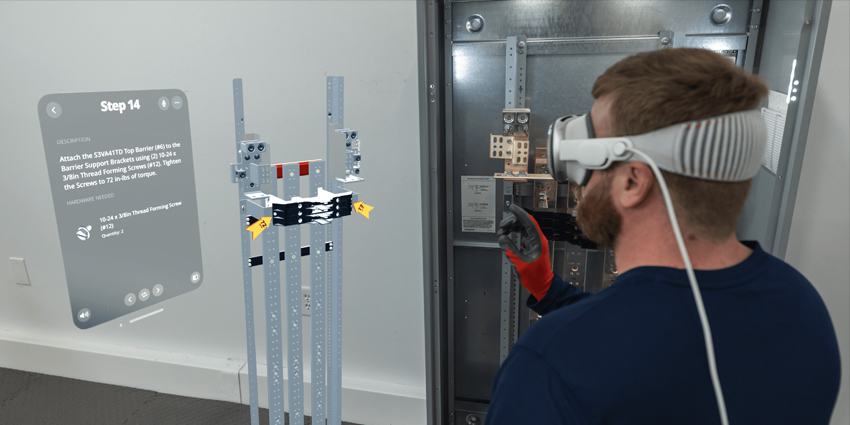

Companies are already using AR headsets in the manufacturing space to provide team members with guidance when they’re on the construction floor. This ensures team members can reach out to specialists in the moment, and get all the guidance they need to stay productive. At the same time, XR tools can bring staff members together for better collaborative experiences when dealing with maintenance issues or repairs.

An MR or AR solution allows engineers to see both the tool they’re working on and the guidance of their subject matter experts in real time, through a set of smart glasses. This improves the chances of an issue being fixed at speed, with minimal requirements for any additional downtime.

The opportunities available for process enhancement through XR will only continue to evolve as new innovations appear in the landscape. For instance, 5G and IoT applications could one day allow professionals to solve issues from a distance.

Step 5: Look at Potential Cost Savings

Although embracing a new technology innovation like XR can seem like an expensive endeavour initially, it could be an opportunity to save money long-term. Using virtual laboratories and digital twins to experiment with designs can be much more affordable (and sustainable) than building prototypes with physical materials.

Extended reality solutions ensure team members don’t have to pay for professionals to fly in from overseas to evaluate a project and do quality assessments. You can even save money on the way you deliver customer service, by connecting with your customers and giving them step-by-step guidance from a distance, without the need for travel.

An XR environment could be the perfect way to create an affordable and eco-friendly environment for better innovation, customer service, and collaboration. As tools become increasingly affordable, there’s a good chance more companies will continue to invest in this ecosystem.